“Simplicity is prerequisite for reliability.” — Edsger Dijkstra

For most of my life, I have struggled to keep down to a healthy weight. It didn’t help when someone told me, “Losing weight is simple. Eat less.” When I protested, they replied, “I said it was simple. I didn’t say it was easy.”

The safest plant is the plant that is never built. Next to that, it’s the plant where nothing breaks and there are no errors. Simple.

Just like losing weight, which if it were easy there would be no obesity, safety would be easy if we could just avoid all malfunctions and mistakes.

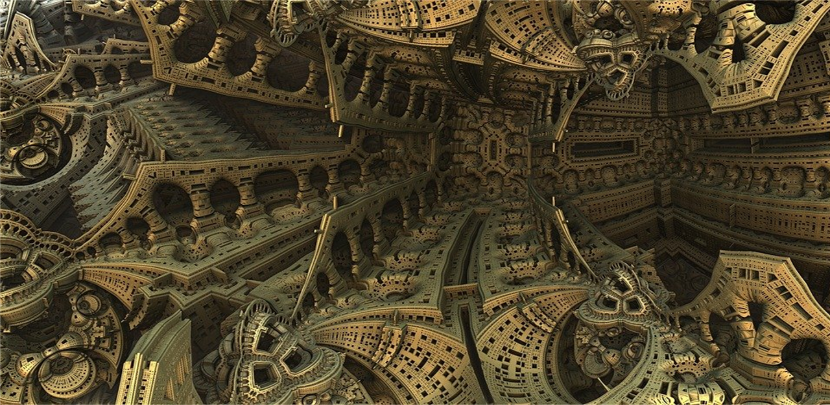

The Opposite of Simplicity

The simpler a process is, both in terms of the number of components that comprise the process and in the number of steps it takes to execute the process, the safer the process. Fewer components mean fewer components to break. Fewer steps mean fewer steps to do incorrectly. And fewer broken components and fewer incorrect actions mean fewer injuries, illnesses, fatalities, and releases to the environment.

The opposite of simplicity is complexity. We tend to make systems more complex. At first, it is because it is easier and faster to meet process design objectives with a complex design than it is with a simpler design. To paraphrase the French philosopher Blaise Pascal, “I have made this design more complex than necessary because I have not had time to make it simpler.”

Unfortunately, no one has as much time as they would like to do the job they want to do. So, they are forced to settle for “will it work?” Even that old safety slogan, “No job is so urgent that we don’t have time to do it safely,” which takes enormous discipline in a milieu of scarce resources, doesn’t translate well into “No project is so urgent that we don’t have time to come up with the safest possible design.”

Flexibility Leads to Complexity

This brings us to a second reason for process complexity.

We often find processes with lots of cross connections, hose connections, drain valves, and vent valves. Why? The reason most often cited is the need for flexibility. What are they, really? Opportunities for making mistakes. In a HazOp, these show up as causes for loss of containment, causes for misdirected flow, causes for reverse flow, and causes for contamination.

The desire for increased flexibility almost always comes at the expense of simplicity in the process design, which in turn leads to a process that is increasingly less safe. The more components there are in a process, the more likely that something will fail. The more steps there are in a process, the more likely that one of them will be missed or done wrong. The greater the number of options, the more likely that the wrong option will be chosen or that the correct option will be executed incorrectly.

Abandoned In Place

A third reason that processes are more complex than they need to be is that they become more complex with time. We make improvements, which means making changes, and the changes we make usually add to the process rather than take away from the process.

Sadly, many changes result in equipment or piping that is no longer used. At first, we leave existing equipment installed because the change might not work out. If so, we want to be able to convert back. Then it’s just there. Then, we call it “abandoned-in-place”, unused, for an indeterminate amount of time, sometimes with the hope that it will be useful to the process again in the future.

Abandoned-in-place shouldn’t mean literal abandonment, but often it does. Abandoned equipment presents hazards that include obstruction and loss of containment. Equipment left in place when new equipment is installed around it may pose the problems of access and egress around the equipment during regular maintenance, firefighting, and emergency escape. Abandoned equipment, including conduits, may provide a path for liquid and vapor to leak into locations where the leak may go unnoticed for an extended period. Underground conduits may even carry materials hundreds of feet from a leak location, making the leak more difficult to find. Even explosions and fires are possibilities.

Simplicity Isn’t Easy

Simplicity isn’t easy, but it’s safer. Because systems have a way of growing more complex with time, it is a constant battle to keep it simple. But as Antoine de Saint-Exupery said, “Perfection is achieved, not when there is nothing left to add, but when there is nothing left to take away.”

The reward is not just a more elegant design, but a safer design. The fewer things there are to break or to do wrong, the less chance there is that something will break or go wrong. At its core, that is the essence of safety: preventing things from breaking or going wrong.