“Don’t rely too much on labels, for too often they are fables.” — Charles Spurgeon

Trick question: “What does PSM require for storage tank labeling?”

Trick answer: “Nothing.”

Helpful answer: “OSHA doesn’t require storage tank labeling under the Process Safety Management (PSM) standard, 29 CFR 1910.119. It does, however, have requirements for storage tank labeling under the Hazard Communication (HazComm) standard, 29 CFR 1910.1200. In fact, there are three options.”

Containers

In the HazComm Standard, OSHA talks a lot about containers. They divide containers into two main categories: shipping containers and workplace containers. Shipping containers are receptacles for transporting hazardous chemicals beyond the workplace. Workplace containers, on the other hand, don’t leave the workplace.

There are two terms here that are worth defining in regard to the HazComm Standard: container and hazardous chemical. A container is “any bag, barrel, bottle, box, can, cylinder, drum, reaction vessel, storage tank, or the like that contains a hazardous chemical. For purposes of this section, pipes or piping systems, and engines, fuel tanks, or other operating systems in a vehicle, are not considered to be containers.” So yes, storage tanks are “containers”. And for the purposes of the HazComm Standard, hazardous chemicals are not limited to those covered under the PSM Standard but are “any chemical which is classified as a physical hazard or a health hazard, a simple asphyxiant, combustible dust, pyrophoric gas, or hazard not otherwise classified.” Some even define water as a simple asphyxiant, so I suppose that by their definition, water is also a hazardous chemical.

OSHA further divides workplace containers into two categories: portable and stationary. Storage tanks are stationary workplace containers.

Labels

The labeling requirements for shipping containers are more rigorous than the requirements for workplace containers. After all, shipping containers go “out there”, while workplace containers stay “in here”.

While OSHA takes great pride in stating that its regulations are performance-based, the labeling requirements for shipping containers are quite prescriptive. There are six. Labels for shipping containers must include:

- Product identifier. Usually the name of the chemical, but it could be a code.

- Signal word. One word to indicate hazard severity: “danger” (worse) or “warning”.

- Hazard statement(s). Prescriptive phrases assigned to each hazard class and category.

- Pictogram(s). One of eight graphic symbols assigned to each of the eight hazard categories.

- Precautionary statement(s). Prescriptive phrases to describe recommended mitigation or preventative measures for the associated hazards.

- Name, address, and telephone number of the manufacturer, importer, or other responsible party.

For workplace containers, which stay “in here”, the list is shorter. Labels don’t need to included item 6, the name, address, and telephone number of the responsible party.

There Are Options

Labeling storage tanks correctly with those five elements—product identifier, signal word, hazard statement(s), pictogram(s), and precautionary statement(s)—assures compliance. But OSHA has allowed for two simpler alternatives.

One is to label the workplace container—the storage tank—with a product identifier (usually, the name of the chemical) and some combination of words, pictures, or symbols that give general information about the hazards of the material. The expectation is that the other parts of the HazComm program (SDSs and training) will serve to fill in the details. It’s up to an inspector, on a case-by-case basis, to decide if the selected combination of words, pictures, or symbols is adequate.

The other alternative, which is only for stationary containers, is really only intended for tanks or vessels where the contents change frequently, making fixed labels impractical. It allows for “signs, placards, process sheets, batch tickets, operating procedures, or other such written materials”, as long as this written material unambiguously conveys the product identifier and the general information about the hazards of the contents.

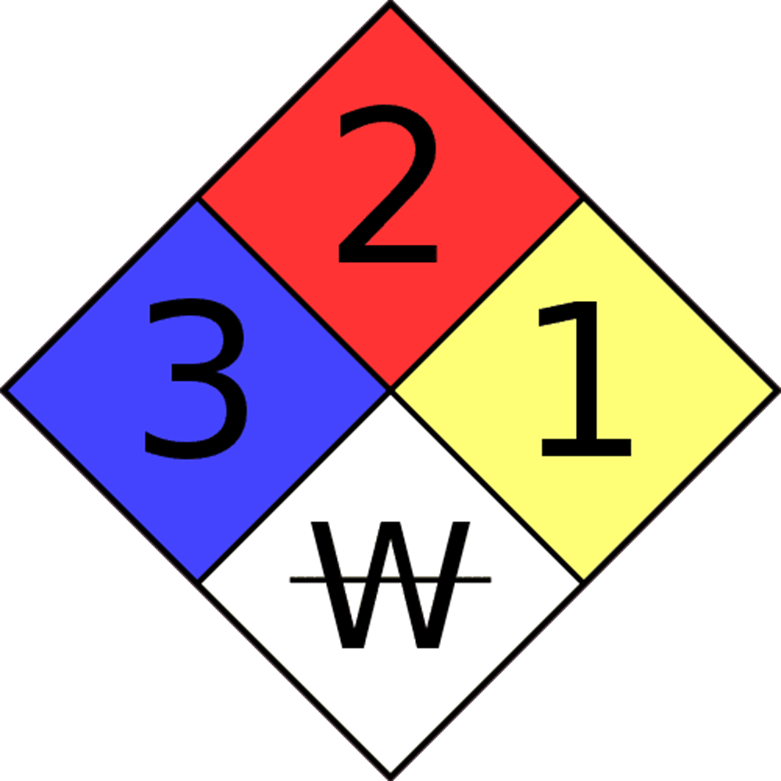

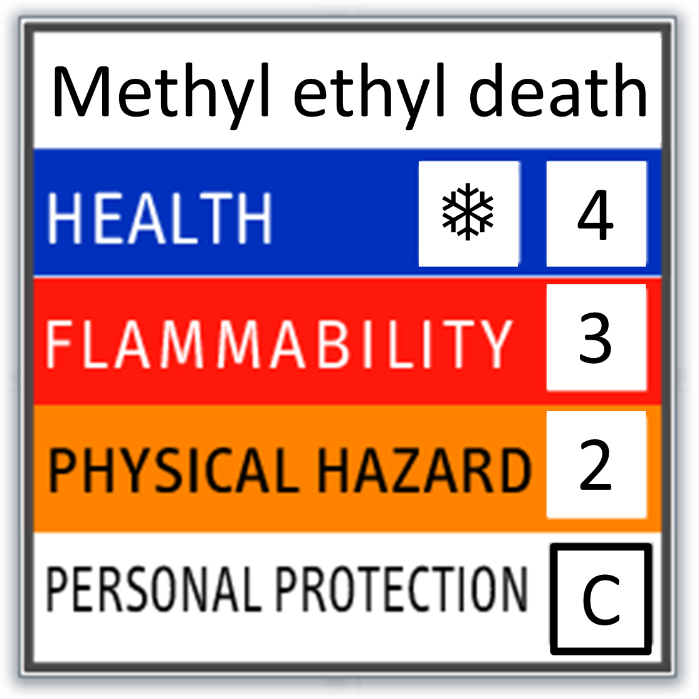

The NFPA Diamond and the HMIS Bars

Before the United States got on board with the UN Globally Harmonized System of Classification and Labeling of Chemicals (GHS), two U.S. organization stepped into the breach to provide a system for communicating the general hazards of container contents. One was the National Fire Protection Association (NFPA), which developed NFPA 704 and the iconic NFPA Diamond. The other was the American Coatings Association, which developed the Hazardous Materials Identification System (HMIS).

Although strikingly similar, they differ in significant ways. They both use a 0 to 4 rating, with 4 being the worst. They use blue for health hazards and red for flammability hazards. The NFPA Diamond is intended for emergency responders, so focuses exclusively on acute hazards. This falls short of OSHA’s requirements, because it doesn’t address chronic health hazards. They both use a white section, but they use them differently. The NFPA Diamond uses white to signify one of three special hazards: water reactive, oxidizer, or simple asphyxiant. (Some vendors have added other special hazards to their label products, but those are not listed anywhere in NFPA 704.) So, storage tank labeling that consists solely of the chemical name and the NFPA Diamond is inadequate, unless there are no chronic hazards. The storage tanks will need words, too.

The HMIS bars, particularly the third iteration, are intended to warn employers and workers of chemical hazards, which is also the intention of the HazComm standard. It uses an asterisk to denote chronic health hazards, it uses orange for physical hazards instead of yellow for reactivity, and it uses white to denote required PPE instead of one of three special hazards. The folks behind HMIS intended for it to satisfy OSHA labeling requirements, and although OSHA won’t come right out and endorse it, it seems that it does. As long as it’s the third iteration, with orange bars and asterisks.

OSHA Expects Storage Tanks to be Labeled

When the question is, “What does OSHA require for storage tank labeling?”, the answer is in the HazComm Standard. OSHA expects the contents to be identified, and for the labeling to be sufficient to warn workers of the hazards and the necessary safeguards to protect themselves from those hazards. OSHA has stipulated one approach that is sure to be compliant: product identifier, signal word, hazard statement(s), pictogram(s), and precautionary statement(s). But it allows others. To use the others though, the plant’s HazComm program must be thorough and effective. OSHA does not require the use of either the NFPA Diamond or the HMIS bars, although the local fire marshal may have a different opinion about the NFPA Diamond.

Labels, Not Fables

Check the labeling on your storage tanks. Are the contents identified? While the preference is to write out the name of the chemical, you can use codes as long as employees clearly understand what the code means. Are the hazards identified? The new HMIS label will do this, but if you are still using the older HMIS labels, you should update them. Mostly, though, the labels need to match what is there. Make sure your storage tank labels aren’t fables.

If I have storage tanks on the plant grounds, that routinely have changing contents, what procedure must I follow as far as NFPA labeling goes in order to stay compliant?